Design and function

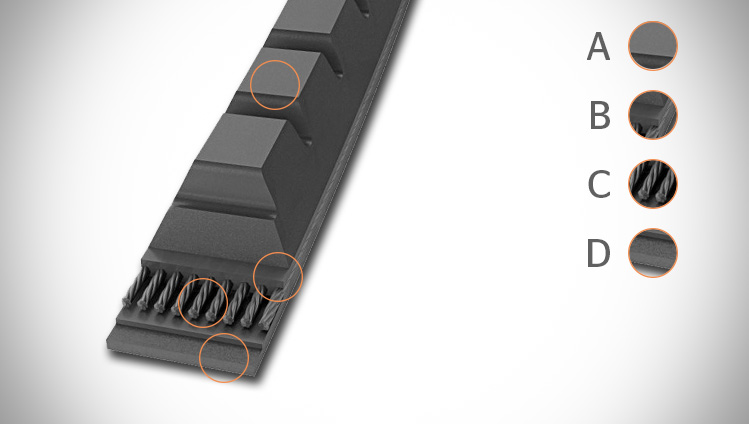

A V-belt consists essentially of:

A) Synthetic rubber base body

B) Tension member bed

C) Polyester tension members

D) Backing fabric

With V-belts, power is transmitted via the static friction on the flanks. They can transmit significantly higher torques than flat belts with the same space requirement. The higher friction on the belt flanks means that the loads on the bearings are substantially lower.

The main field of application is in simple two or three-pulley drives.

Notes

Replacement interval:

V-belts are subject to aging and wear. They therefore have to be regularly checked and replaced. The checking and replacement intervals are always specified by the vehicle manufacturer and must be complied with.

Continental recommends changing the belt every 120,000 km if in doubt.

Storage:

- Store in a dry, dust-free and cool place (ideally 15-25°C)

- Avoid direct sunlight

- Avoid contact with all liquids (oil, water etc.)

- Maximum storage period: 5 years from date of production

Tips:

- Continental V-belts are maintenance-free and do not require retensioning. If the belt is squeaking, the only solution is to change it.